繁/简体中文

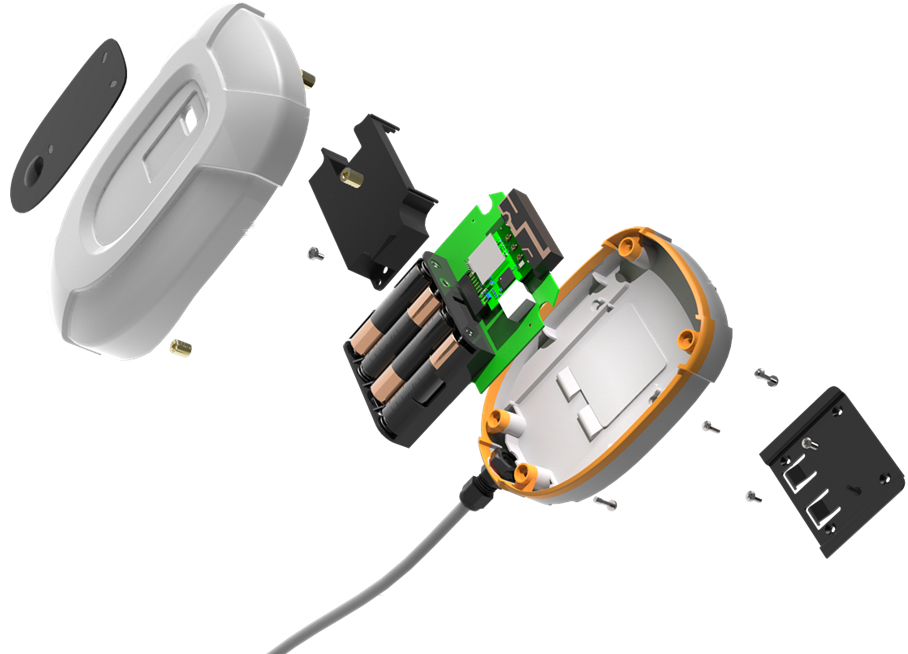

PCB Assembly

Linear Electronics is a full service, high-mix, high complexity, mid to low volume global Electronics Manufacturing Services (EMS) and Custom Material Solutions (CMS) company, providing complete end-to-end supply chain management solutions in electronic and mechanical products for Original Equipment Manufacturers (OEMs).

PCB Assembly

At Linear Electronics, we pride ourselves on our high quality and competitive PCB assembly services. With over 10 years of experience, our strengths lie in achieving the lowest cost possible for the highest level of quality and prompt delivery to a wide range of customers. Our services take your project from design to production and every stage in between, including PCB design, component procurement, mixed assembly and functional testing. We remain on the cutting edge of technology by continually investing in industry leading mounting tools and AOI machinery.

Our specialisms include:

Pick and place of surface mount components down to 01005 and uBGAs

Conventional through-hole soldering

FR4, T-clad, steel and ceramic substrates

Serialisation and barcoding

Conformal coating and encapsulation

ISO9001 : 2008 accreditation

All workmanship carried out to IPC J-STD

All inspections carried out to IPC-A-610

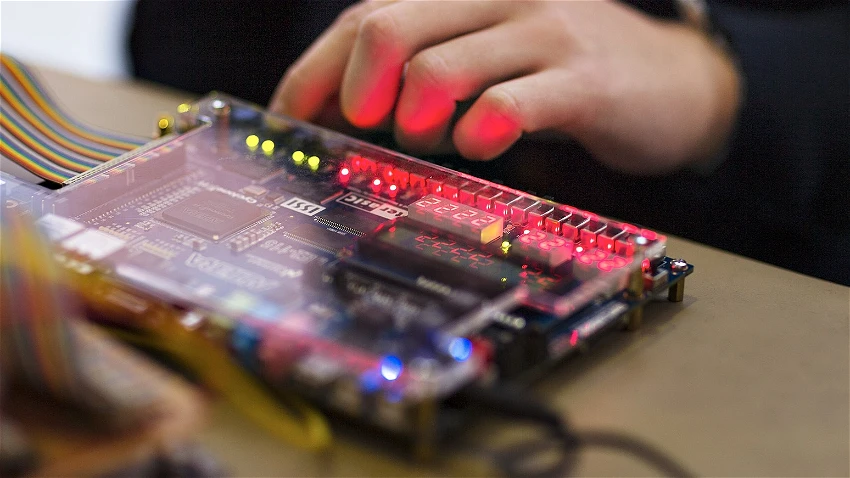

We use both conventional PCB assembly and Surface Mount Technology (SMT) component placement systems, ensuring we are industry-leading through our continual investment in the latest machinery:

Solder Paste Printing –

3D Solder Paste Inspection-

Pick-and-Place –

QR coded smart reel system

Reflow –

Selective Soldering –

3D AOI –

Getting a Quote

Our process starts with the customer sending through an RFQ pack containing Gerber files, Bill of Materials and PCB Spec alongside any additional info, such as a test specification. Then, our production engineering team studies the documentation for any discrepancies before our purchasing experts quote for the PCB and components and our production planner adds lead time and labour costs. With this information, our sales team issues the quote to the customer stating price, lead time and any component alternatives.

Our Process

After receiving an order, the first step is to raise a sales order and complete our in-house checklist to ensure all provided documentation is correct. Our production engineering team then review all documentation to double check it is correct regarding details like issue numbers, part numbers and more. Once this is complete, our purchasing team begin procuring components. At Linear Electronics, traceability is key and due to the systems we have in place, all components are traceable down to batch and board level. Once all components are at the production line, we send an acknowledged shipping date to the customer to meet the delivery time we quoted. Once assembled, all builds are inspected by our state-of-the-art 3D AOI Inspection system as well as being visually checked by our IPC-A-610 trained quality engineers. We are able to offer flexible supply options including Kanban supply to support your Lean Manufacturing system, and we have the capacity to hold stock of components and final assembly.

Our Customers

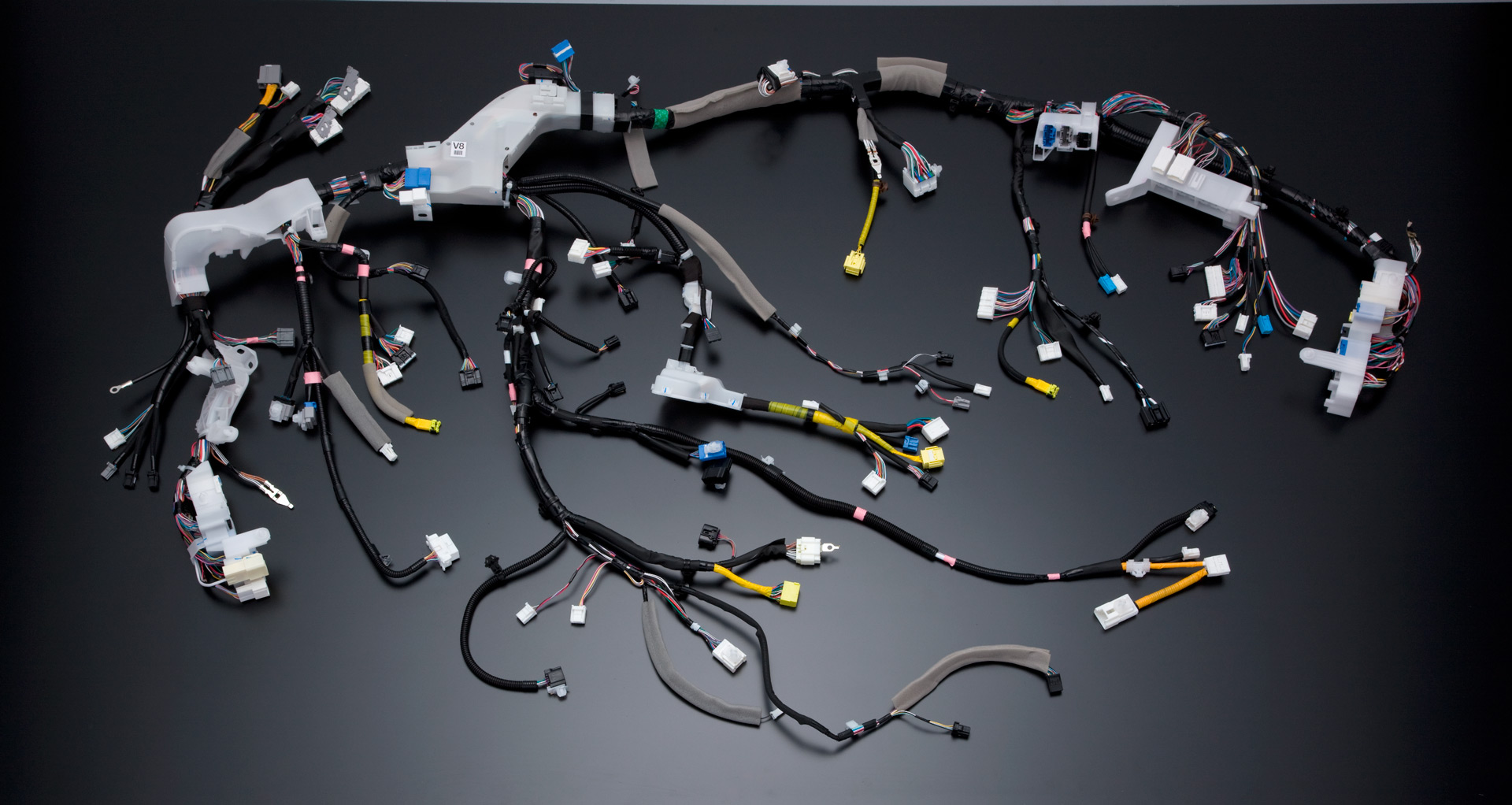

Our customer network is made up of a range of industries and business sizes that all value a high quality and reliable PCB assembly manufacturer. A significant portion of our client base include the aerospace and defence industries, for which our UK manufacturing facilities and AS9100 accreditation make us the ideal PCBA services partner, though of course these aspects of our services benefit all of our builds. We work with many other sectors including medical, industrial, oil and gas, energy, automotive and more. In fact, the flexibility of our printed circuit board assembly services (including both small and large batch and fast turnaround options) means we’re able to cater to a vast range of customers.

Our Benefits

Linear Electronics provides small batch or high volume production as well as full functional testing, quality assurance and global component sourcing options. With manufacturing facilities in the UK and Far East, we offer competitive pricing across all our PCB manufacturing services. Our continual investment in the latest technology including solder paste printing, pick-and-place and selective-soldering, means we can offer fast turnaround services and maintain short lead-times.

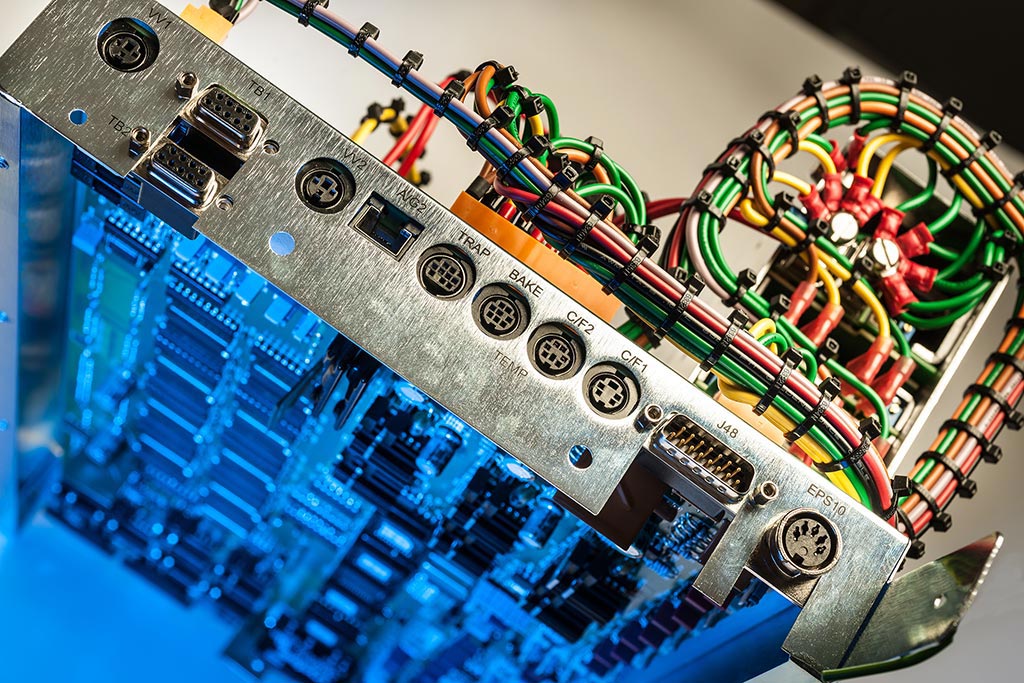

Our Quality Control Measures

Quality has always been of paramount importance at Linear Electronics. We deliver all products in accordance with our ISO9001 accreditation as well as ISO2008 certificate. Our PCB assembly quality processes mean we are able to identify potential issues at the earliest opportunity through quality experts performing visual inspection and circuit testing as well as all builds passing through our state-of-the-art automated optical inspection machinery. All products at Linear Electronics are manufactured to J-STD-001 workmanship standards and inspected in accordance with IPC-A-610 quality classifications.

PCB Layout Services

Alongside PCB assembly, our engineering team combines years of experience in the electronics industry with leading software to offer multi-layer PCB design and layout services.

Request a Quote

If you would like to receive a PCB assembly quote for your project, simply send us your Bill of Materials (BOM) and PCB data for a quote. You can do this by simply to sales@linear-electronics.com