繁/简体中文

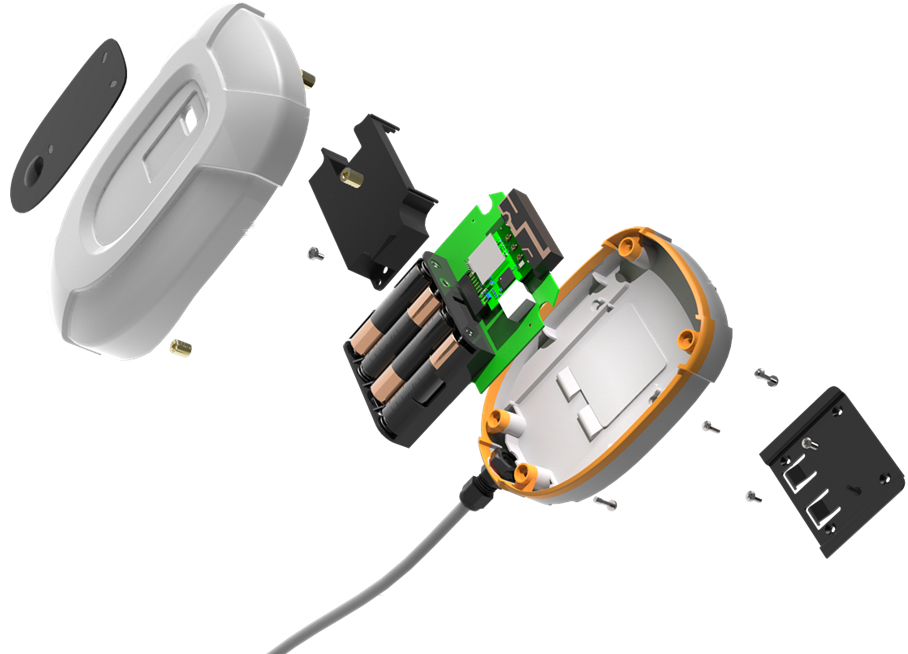

Wire Harnessing & Cable Assembly

Linear Electronics is a full service, high-mix, high complexity, mid to low volume global Electronics Manufacturing Services (EMS) and Custom Material Solutions (CMS) company, providing complete end-to-end supply chain management solutions in electronic and mechanical products for Original Equipment Manufacturers (OEMs).

From simple to complex assemblies with discrete, and/or multi-jacketed cable and wire, Linear Electronics provides wire harness design, complete wire harnessing, and wire harness assembly. We provide a wide range of electronic cable assemblies that address I/O, power, and signal applications. Many of the configurations include industry standards such as:

Cat 5E,

DVI,

HDMI,

RJ45,

RS232,

RS422,

RS485,

SCSI,

Car Cable

Power Cable

and USB to name a few.

We manufacture to customer supplied documentation or provide consultative design services for manufacturability to assist with the component material specifications and design layout. Linear Electronics can support your product life cycle from product development to volume production.

****************************************************************************************************************

Wire harness

What comes to mind when you hear the word “harness assembly”? Like many people, you may be inclined to imagine a mechanism of loosely organized cables or wires. Although this description is partially correct, harness assemblies can be used for more useful purposes. Today’s blog post will delve into the world of harness components.

Here, we will answer some of the most common questions related to harnessing components. To do this, we will start with definitions.

What is a harness assembly?

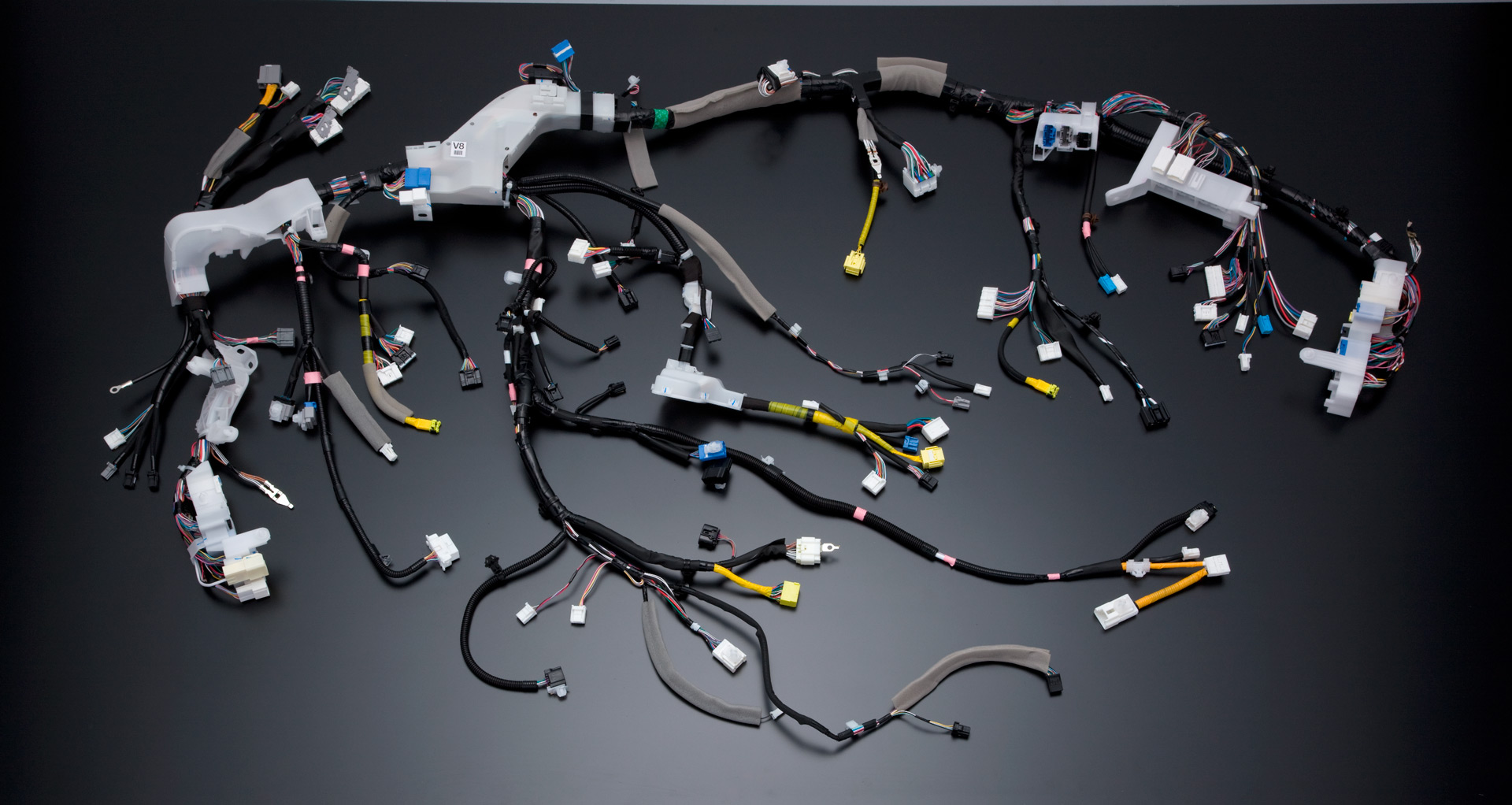

At the most basic level, a harness assembly is a set of cables or wires that work together to relay power or information and command signals. These cables and wires are usually wrapped in a basic thermoplastic or thermosetting shell to prevent external forces from affecting the structural integrity of the exposed cables and wires.

By bundling cables and wires into a single instrument, the harness assembly acts as an organizing mechanism to reduce the amount of space that would otherwise be occupied by separately installed cables and wires.

Benefits of using harness assemblies

A harness assembly is an important tool for the operation of electrical systems around the world. They are often combined because they improve the efficiency of these systems. In this section, we will discuss two main reasons for the popularity of harness components: organization and protection.

Harness assembly saves valuable space

Have you ever gone into the attic to get the lights during Christmas and found the wires hopelessly entangled? If you are one of those who have experienced this event, you can sympathize with how frustrating it is to separate these from each other.

When you apply the previous example to a loose set of cables or wires, you will quickly understand the need for organizational mechanisms. Compared with the loose Christmas lighting, a disorderly interlocking and cross cable and wire system may be the same (if not more) heavy work. This is especially true if dozens of cables and wires need to be replaced or rearranged.

One of the main benefits of using harness assemblies is that it organizes your cable and wire layout. By aggregating cables and wires under a single enclosure, the harness organizes your cable/wire setup by reducing the space required to accommodate the layout.

To further illustrate this, please consider taking you to work by car or flying you to your favorite holiday destination. Both cars and airplanes require thousands of feet of wiring to operate effectively and efficiently. Therefore, instead of connecting a large number of cables and wires separately, the harness assembly combines the cables and wires into a single device and then easily installs them.

In short, if you are a person who values organization and order, harness components will change your life.

Harness assemblies protect cables and wires

The harness assembly can not only be used as an organization tool but also protect the functionality and durability of cables and wires. Over time, interconnect and cross cable and wire settings may result in poor performance and damage to cables/wires. Using harness assemblies to organize cables and wires can minimize functional degradation and potential damage caused by external forces. More specifically, the outer thermoplastic or thermosetting shell of the seat belt acts as a basic buffer against the negative effects associated with moisture, tearing, and accidental vibration.

In addition, the harness assembly can prevent electrical damage. The insulating sheath covering the bundled cables and wires helps prevent electric shock to those who use them. In addition, since the sheaths of the grouped cables and wires constituting the harness assembly are firmly bound, the possibility of an electrical short circuit is reduced.

Harness assemblies are important elements in the global electrical system because they provide organization and enhanced protection for cables and wires. The next section describes how to harness components are used in various industries.

Multiple applications of harness assembly

Harness assemblies have many different applications. The application list covers many industries and sectors, including but not limited to agriculture, automobile, communication, manufacturing, and medical sectors.

Agricultural industry

Many types of equipment and vehicles used in the agricultural sector today use harness assemblies. The organization and protection function of the harness assembly ensures that heavy machinery (such as tractors and cultivators) operates throughout the year.

Automobile industry

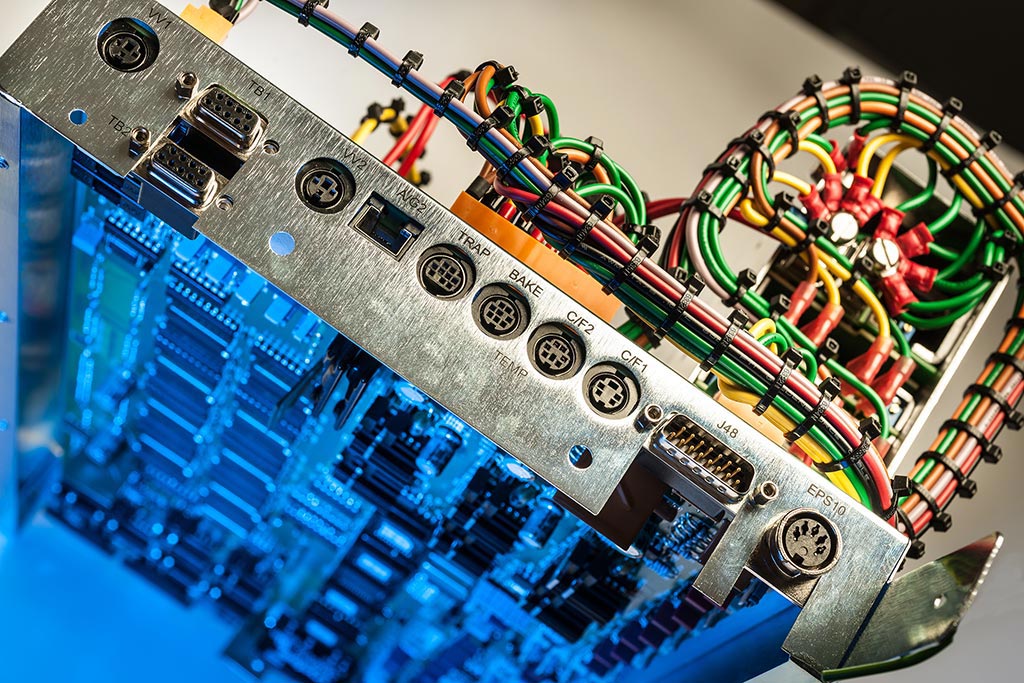

The harness assembly is installed in the vehicle to help distribute power and electrical signals throughout the vehicle. The power and signals through the wire harness help to start the ignition, turn on the lights, cool and heat the car, listen to the radio and roll down the windows.

communication system

The global communication system relies on harness components to connect the world. From modems to routers, from broadband networks to satellite receivers, harness assemblies play an important role in powering the infrastructure that makes instant messaging possible.

medical technology

It can be said that modern medical care is impossible if the harness assembly is not integrated into the equipment used for treating modern diseases in the doctor’s office and hospital. Medical devices often require frequent operation and must rely on the durability and versatility of the harness assembly to help maintain function.

Industry and manufacturing

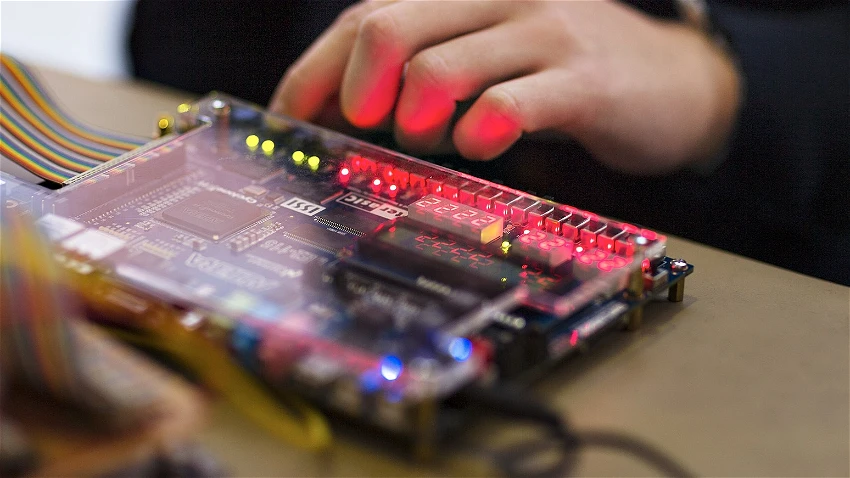

Harness assemblies are often used in industrial control and manufacturing processes. Because assembly lines and production systems require complex cable and wire systems to drive automation, the harness assembly organizes these fine cable and wire connections to simplify the production process to ensure that larger manufacturing components are optimized.

Taken together, harness components are common features in the global electrical system. Without them, modern technology might not be so effective.

Difference between harness assembly and cable assembly

A common assumption about harness assemblies is that they can be interchanged with cable assemblies. Harness assemblies are often confused with cable assemblies because they all have similar functions. However, they are not the same.

Harness as

As a brief review, the harness assembly is a collection of bundled cables and wires wrapped by a designed basic thermoplastic or thermosetting material. The design of the harness assembly sheath is very simple, which can make the cable installation orderly and provide basic external protection. This basic structure defines the harness assembly as the most suitable for indoor use with minimal external impact.

Cable as

Similar to the harness assembly, the cable assembly consists of bundled cables and wires. However, the materials that wrap them tend to be more durable. The cable assembly housing is typically made of materials such as vinyl or thermoplastic rubber that enable the device to operate in the most intense environments where the external environment is ubiquitous. Compared to harness assemblies, cable assemblies are generally most suitable for outdoor use or in environments that operate under various stresses, such as heat, moisture, and friction.

If you are interested in further understanding the more complex details of the differences between the harness assembly and the cable assembly, please read our title “cable assembly vs. Harness”.

Design harness assembly

The harness assembly is usually designed to meet the needs of the purchasing agent. The number of cables and wires in the harness assembly may vary depending on the customer’s specifications and energy requirements. In its most basic form, the harness assembly may contain only a few cables or wires, and only the most necessary terminals are installed.

On the other hand, for an electrical system that requires various operations and functions, the harness assembly may contain a variety of cables and wires. Without the harness, they are like an endless maze. Finally, the complexity of the design will be affected by its design function. Meridian cable is specially designed for simple to complex harness components for various purposes.

Get the perfect harness for your application

If you need a customized harness in the market, Linear electronics can help you. Our team is committed to creating the highest quality and customizable harness components for our OEM customers. We have the ability to design harness components for all types of applications. We guarantee that we will customize the perfect harness assembly to meet your necessary specifications. Or, if you do not consider a specific design, we also provide a large number of prefabricated products to ensure that your needs are met.